PRODUCTS

55% Galvalume steel coils

Keywords:

Galvanized steel coil

Prepainted aluminum sheet

Catalog:

- Details

-

The characteristics of 55% aluminum-zinc plated steel sheet are as follows

● Corrosion resistance

The corrosion resistance of aluminum-zinc plated steel sheet is derived from the barrier layer protection function of aluminum and the sacrificial protection function of zinc. When zinc is used as a sacrificial protection for cut edges, scratches, and abrasions to the plating, aluminum forms an insoluble oxide layer, which performs the barrier protection function. Long-term atmospheric exposure tests of 55% Aluminum-Zinc plating in various regions of the world, such as rural areas, industrial areas, general coastal areas, and harsh marine areas, have confirmed that 55% Aluminum-Zinc plating is 2-4 times more resistant to corrosion than zinc plating at the same coating thickness.

● Heat Resistance

Aluminum-zinc plated steel sheets have better heat resistance than galvanized steel sheets, and can be used in high-temperature environments up to 315°C without discoloration and contamination, but galvanized steel sheets are not suitable for environments above 230°C. The 55% aluminum-zinc alloy plated steel sheet has excellent high-temperature oxidation resistance and heat reflection because of its highly reflective power, which makes it a heat-resistant barrier.

● Formability

The aluminum-zinc alloy coating is harder than the galvanized coating, but because of its excellent adhesion to the steel sheet, it has the same formability as the galvanized steel sheet as long as the minimum bending radius and lubricant coating are followed, so it is possible to meet the needs of applications such as stamping (DQ) and deep-drawn blanking (DDQ).

● Paintability

Aluminum zinc plating is ideal for painting applications, and its unique coating organization provides excellent film adhesion and good ductility, resulting in outstanding performance.

● Weldability

Since the aluminum content of the zinc-aluminum coating is 55%, the welding conditions are different from those for general galvanized steel, such as the welding current, the welding cycle, and the welding pressure should be adjusted. More suitable welding methods are: a. Resistance point fusion welding; b. Resistance protrusion fusion welding; c. High / low frequency fusion welding; d. Gas Metal Pole Arc Welding (is a kind of continuous delivery of consumable wire and the base material to produce arc heat, so that the weld channel into a molten state, and then in the arc and weld channel around the molten pool covered with protective gas welding method, the early days known as the MIG, Metal Inert Gas Welding method, and thereafter. In order to comply with the welding of various materials, respectively, developed a variety of mixed gas shielded welding method, so also known as MAG, Metal Active Gas welding method).

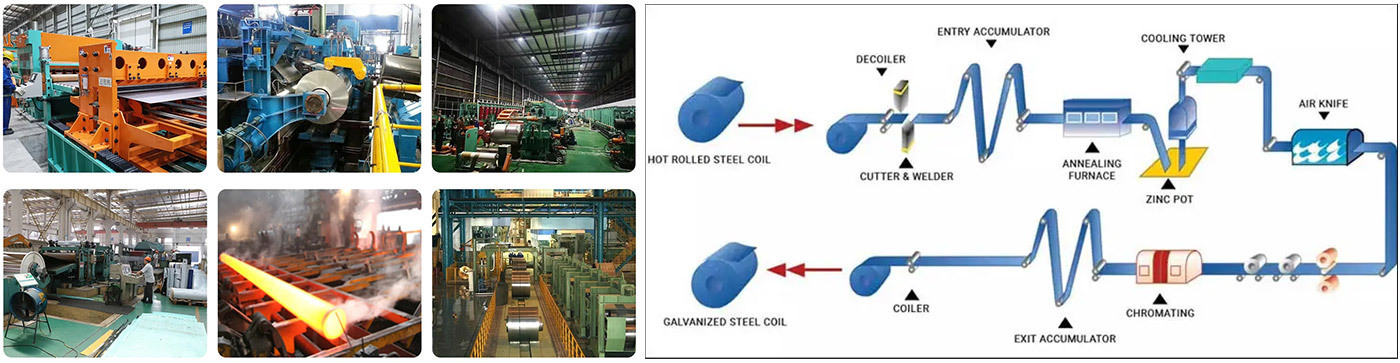

Technology

Packing and shipping

Our products have been exported to Southeast Asia, the Middle East, South America, Europe, Oceania and other countries and regions, enjoying a good reputation. The product packaging has an inner layer of waterproof paper and an outer layer, iron packaging, and wooden pallets that are fumigated and fixed. It can effectively protect products from corrosion during ocean transportation. Domestic and foreign customers are welcome to call us for consultation and ordering.

MORE PRODUCTS

Leave A Message